Recommended products

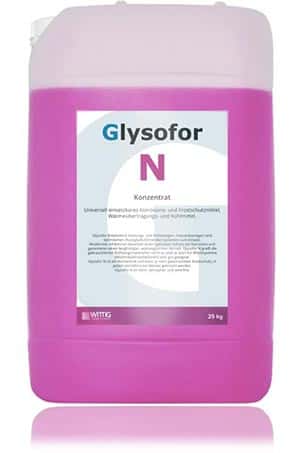

Glysofor N

Antifreeze concentrate based on monoethylene glycol

Glysofor L

Antifreeze concentrate based on propylene glycol

Effective solutions to your business.

Glysofor is a cooling medium that ensures reliable system functions at all times during process cooling and therefore ensures an efficient and optimised production process.

The range of applications covers a wide range of industries in which reliable process cooling is decisive for the manufacturing process.

Plastics industry

Glysofor ensures reliable process cooling in injection moulding systems, extrusion systems and blow moulding machines for constant moulded parts cooling. Cooling using water is only possible when the temperature is above 0 °C, whereas Glysofor remains liquid and functional down to a temperature of -50 °C. This means that significantly lower temperatures can be generated for mould cooling, which enables significantly shorted cooling times and can contribute to production increases.

Metal & steel industry

Regardless of whether you want to reduce the temperature of finished metal products or require reliable cooling for tool machines, laser systems and cutting systems, Glysofor helps you to reach the required process temperatures.

Chemicals & pharmaceuticals

Constant temperatures and heat dissipation are decisive for reactions in petrochemical processes, when manufacturing medication, or other manufacturing processes in chemical and pharmaceuticals production. Using Glysofor as a heat transfer medium or coolant enables exact temperature control in the entire process.

Vehicle and machinery construction

Process cooling is decisive in automotive construction. Using Glysofor can ensure that machines for production, test and development processes are kept at the optimum temperature.

Technical building equipment

Cooling and air conditioning systems are an important characteristic in technical building equipment (TBE) in factories and warehouses, as well as in clinics, office buildings or superstores. Glysofor is used here as a heat transfer medium or a coolant and provides reliable frost and corrosion protection for long-term, low-maintenance operation of heating ventilation and air conditioning systems (HVAC).

IT and computer centres

Overheating can become a major problem for IT computer centres and cause high costs due to downtimes and unplanned maintenance work. Connected loads of several kW per rack are common nowadays and therefore, even small server rooms at medium sized companies require cooling outputs of tens of kilowatts. Using precision air conditioning units with water and glycol circuits has proven its worth here. Glysofor is used as a heat transfer medium and prevents the outdoor cooler freezing at winter temperatures.

Surface temperature control

In ice hockey stadiums, Glysofor is used to create artificial ice surfaces by being brought to a temperature of -10° to -12° C in the cooling piping, so that water can be sprayed over it to freeze and form an ice surface. On the other hand, in football stadiums, under-soil heating is used to enable games to be played in winter when the temperature is below zero and if snow has fallen. The plastic pipes that are installed below the roots are filled with Glysofor and keep the playing surface a few degrees above freezing. In addition, the entire system is protected against frost damage on days when there are no games. Glysofor can therefore work as a cooling or a heat transfer medium and ensure constant temperatures in ice surfaces in ice hockey stadiums or frost-proof operation of grass heating systems in football stadiums.